Cactus Mine Project – Overview

The Cactus Project is comprised of three deposits and one waste dump within a 4 km mine trend, including the past producing Sacaton Mine, the deposits now known as Cactus East and Cactus West. Immediately southwest of the Cactus deposits is the Parks/Salyer deposit, SW along the mine trend.

The Cactus and Parks/Salyer deposits are portions of a large porphyry copper system that has been dismembered and displaced by Tertiary extensional faulting. Porphyry copper deposits form in areas of shallow magmatism within subduction-related tectonic environments (Berger et al., 2008). Cactus has typical characteristics of a porphyry copper deposit which Berger et al. (2008) define as follows:

- One wherein copper-bearing sulphides are localized in a network of fracture-controlled stockwork veinlets and as disseminated grains in the adjacent altered rock matrix.

- Alteration and mineralization at 1 km to 4 km depth are genetically related to magma reservoirs emplaced into the shallow crust (6 km to over 8 km), predominantly intermediate to silicic in composition, in magmatic arcs above subduction zones.

- Intrusive rock complexes that are emplaced immediately before porphyry deposit formation and that host the deposits are predominantly in the form of upright-vertical cylindrical stocks and/or complexes of dikes.

- Zones of phyllic-argillic and marginal propylitic alteration overlap or surround a potassic alteration assemblage.

- Copper may also be introduced during overprinting phyllic-argillic alteration events.

The Company completed a PFS in Q1 2024, ascertaining initial project economics of all leachable ores including the Stockpile Project, Cactus West, Cactus East and Parks/Salyer. The PFS outlined a 55kstpa heap leach and SX/EW operation extending over 21 years, producing LME Grade A copper cathodes directly onsite. The Company is currently advancing the Cactus Project to a PEA targeting the integration of MainSpring and a second scenario showing the Nuton Technologies upon primary sulphides. Subject to a positive outcome from the PEA and subsequent PFS, the Company plans to subsequently complete a DFS in 2025.

Project Highlights

- Private land package and 100% ownership in Tier 1 jurisdiction

- Brownfield, scalable development project with onsite power, rail and water in place

- Simple heap-leach and SXEW operation

- Permitting framework is simple and streamlined with the state

- Next steps include:

- PEA in Q3 2024

- Metallurgy and infill drilling

- PFS

- DFS

- Construction Decison

Primary Sulphide Leaching Potential

Recent preliminary metallurgical work with Rio Tinto’s NutonTM technologies has demonstrated through column leach testing, encouraging copper extraction rates with a targeted rate of 80% over the life of mine. Nuton will continue to test the application of its copper heap-leach related technologies to the primary sulphide component of the Cactus Mine and Parks/Salyer Projects through column leaching and scoping out capital and operating costs and design parameters within a heap leach and SX/EW flowsheet. If successful, the NutonTM sulphide leaching technology unlocks the following:

Mineral Resources and Reserves

|

|

Cactus Project Mineral Reserves (As at February 21, 2024) |

|

|

Proven + Probable |

Tons |

276,286,000 |

|

|

CuT (%) |

0.549 |

|

|

Cu TSol (%) |

0.484 |

|

|

Cu (M lbs) |

3,031.0 |

Notes:

- Mineral Reserves have an effective date of November 10, 2023. The Qualified Person for the underground estimates of Cactus East and Parks/Salyer is Nat Burgio of AGP Mining Consultants Inc. The Qualified Person for the open pit estimates of Cactus West and Stockpile is Gordon Zurowski of AGP Mining Consultants Inc.

- The Mineral Reserves were estimated in accordance with the CIM Definition Standards for Mineral Resources and Reserves.

- The Mineral Reserves are supported by a combined open pit and underground mine plan, based on open pit and underground designs and schedules, guided by relevant optimization procedures.

Inputs to that process are:- Metal prices of Cu $3.70/lb.

- Processing costs which are variable and based upon material type, processing destination, copper grade, and copper recovery. Processing costs include a fixed unit cost component, a net acid consumption cost, and a cost for refining and selling copper cathode.

- General and administration cost of $0.47/ton processed.

- Royalty cost of 2.5% for Parks/Salyer and 2.54% for Cactus/Stockpile Ores.

- Process recoveries which are variable depending upon mineralization type, sequential copper grades, and comminution size.

- Open pit geotechnical design criteria from Call and Nicholas, Underground geotechnical design criteria from Call and Nicholas, Open pit mining costs including an escalation factor with pit depth.

- Underground mining cost of $27.62.

- The footprint delineations for the Cactus East and Park Slayer mines were based on a resource model block cash flow dollar value (CFTC1) of $27.62 (net of process, G/A and royalties). Drawpoints were shut-off when the grade value fell below a CFTC1 of $27.62 following the necessary removal of swell material within the footprint.

- Dilution and mining loss adjustments are incorporated into the underground mining inventories by way of cave flow modelling software. Inferred resources included in the mixing process have been assigned zero grade. No allowance for mining dilution or ore loss has been provided in the open pit mining inventories

The mineralized domains are consistent with domaining for porphyry copper systems. Mineralized domains represent combinations of rock type and copper mineral zonation associated with secondary copper enrichment weathering processes. The main mineral zones being leached, oxide, enriched, and primary. Mineral zones are determined by logging and the assay attributes of sequential copper analyses. Resources considered for beneficial processing within the 2024 Prefeasibility Study are related to four sources:

- An existing mine stockpile built during the development and operation of a copper open pit and milling facility from 1974 to 1984. The stockpile includes oxide and lower grade sulphide material containing primarily copper mineralization. • Further development of the existing Cactus West open pit containing oxide and lower grade sulphide material.

- The underground resource called Cactus East located northeast immediately adjacent to the existing Cactus open pit and at a depth of 1,200 ft. This resource contains mostly lower-grade sulphide material.

- The underground resource called Park Salyer located about 1 mile to the southwest of the Cactus West open pit at a depth of 1,500 ft. This resource contains mostly higher-grade secondary and primary copper sulphide material.

|

Material Type |

|

|

|

|

|

(Kt) |

% |

% |

Cu (Klbs) |

|

|

MEASURED |

||||

|

Cactus |

||||

|

Oxide |

200 |

|

0.137 |

500 |

|

Enriched |

8,900 |

|

0.232 |

41,400 |

|

Total Leachable |

9,100 |

|

0.230 |

41,900 |

|

Primary |

1,300 |

0.315 |

|

8,000 |

|

Total Measured |

10,400 |

0.241 |

49,800 |

|

|

INDICATED |

||||

|

Cactus |

||||

|

Oxide |

73,300 |

|

0.352 |

515,800 |

|

Enriched |

73,900 |

|

0.661 |

977,400 |

|

Total Leachable |

147,200 |

|

0.507 |

1,493,200 |

|

Primary |

73,000 |

0.348 |

|

507,600 |

|

Total Indicated |

220,300 |

0.454 |

2,000,800 |

|

|

Stockpile |

||||

|

Oxide |

71,100 |

|

0.153 |

217,300 |

|

Parks/Salyer |

||||

|

Oxide |

10,000 |

|

0.921 |

183,700 |

|

Enriched |

120,200 |

|

1.037 |

2,493,000 |

|

Total Leachable |

130,200 |

|

1.028 |

2,676,600 |

|

Primary |

13,800 |

0.833 |

|

229,400 |

|

Total Indicated |

143,900 |

1.009 |

2,906,100 |

|

|

INFERRED |

||||

|

Cactus |

||||

|

Oxide |

33,000 |

|

0.326 |

214,900 |

|

Enriched |

29,000 |

|

0.374 |

216,800 |

|

Total Leachable |

62,000 |

|

0.348 |

431,700 |

|

Primary |

122,300 |

0.342 |

|

837,100 |

|

Total Inferred |

184,300 |

0.344 |

1,268,800 |

|

|

Stockpile |

||||

|

Oxide |

1,200 |

|

0.127 |

3,000 |

|

Parks/Salyer |

||||

|

Oxide |

8,700 |

|

0.925 |

161,700 |

|

Enriched |

35,700 |

|

0.996 |

711,500 |

|

Total Leachable |

44,500 |

|

0.982 |

873,200 |

|

Primary |

3,900 |

0.797 |

|

62,900 |

|

Total Inferred |

48,400 |

0.967 |

936,100 |

|

Notes:

- Leachable copper grades are reported using sequential assaying to calculate the soluble copper grade. Primary copper grades are reported as total copper, Total category grades reported as weighted average copper grades of soluble copper grades for leachable material and total copper grades for primary material. Tons are reported as short tons.

- Stockpile resource estimates have an effective date of 1 March 2022, Cactus resource estimates have an effective date of 29th April 2022, Parks/Salyer resource estimates have an effective date of 19th May 2023. All resources use a copper price of US$3.75/lb.

- Technical and economic parameters defining resource pit shell: mining cost US$2.43/t; G&A US$0.55/t, 10% dilution, and 44°-46° pit slope angle.

- Technical and economic parameters defining underground resource: mining cost US$27.62/t, G&A US$0.55/t, and 5% dilution

- Technical and economic parameters defining processing: Oxide heap leach (HL) processing cost of US$2.24/t assuming 86.3% recoveries, enriched HL processing cost of US$2.13/t assuming 90.5% recoveries, Primary mill processing cost of US$8.50/t assuming 92% recoveries. HL selling cost of US$0.27/lb; Mill selling cost of US$0.62/lb.

- Royalties of 3.18% and 2.5% apply to the ASCU properties and state land respectively. No royalties apply to the MainSpring (Parks/Salyer South) property.

- For Cactus: Variable cutoff grades were reported depending on material type, potential mining method, and potential processing method. Oxide material within resource pit shell = 0.099% Tsol; enriched material within resource pit shell = 0.092% Tsol; primary material within resource pit shell = 0.226% CuT; oxide underground material outside resource pit shell = 0.549% Tsol; enriched underground material outside resource pit shell = 0.522% Tsol; primary underground material outside resource pit shell = 0.691% CuT.

- For Parks/Salyer: Variable cut-off grades were reported depending on material type, associated potential processing method, and applicable royalties. For ASCU properties - Oxide underground material = 0.549% Tsol; enriched underground material = 0.522% Tsol; primary underground material = 0.691% CuT. For state land property - Oxide underground material = 0.545% Tsol; enriched underground material = 0.518% Tsol; primary underground material = 0.686% CuT. For MainSpring (Parks/Salyer South) properties - Oxide underground material = 0.532% Tsol; enriched underground material = 0.505% Tsol; primary underground material = 0.669% CuT.

- Mineral resources, which are not mineral reserves, do not have demonstrated economic viability. The estimate of mineral resources may be materially affected by environmental, permitting, legal, title, sociopolitical, marketing, or other relevant factors.

- The quantity and grade of reported inferred mineral resources in this estimation are uncertain in nature and there is insufficient exploration to define these inferred mineral resources as an indicated or measured mineral resource; it is uncertain if further exploration will result in upgrading them to an indicated or measured classification.

- Totals may not add up due to rounding

Cactus Mine Project NI 43-101 Technical Report and Pre-feasibility Study Arizona, United States of America

The finalized Cactus PFS details a 55kstpa heap leach and solvent extraction and electrowinning operation over 21 years for the onsite recovery of copper to LME Grade A cathode standards. The PFS integrates ore from four sources; Parks/Salyer, Cactus West, Cactus East, and the Stockpile Project.

PFS Summary

Cactus PFS Summary:

|

Assumption / Outcome |

Value / Results |

|---|---|

|

Copper Price |

US$3.90/lb |

|

Mine LIfe |

21 years |

|

Total Mineralized Material Moved |

276 Mtons |

| Total Waste | 147 Mtons |

| Average Acid Consumption | $18.99/lb |

| Production | |

| Average Head Grade | 0.48% Cu TSol |

| Average Recovery Rate (CuAS) | 90.8% |

| Average Recovery Rate (CuCN) | 84.5% |

| Total Payable Copper | 2,306 Mlbs |

| Annual Payable Copper | 110 Mlbs (55kstpa) |

| Operating Costs | |

| Mining Cost (per ton mined) | US$7.50 |

| Mining Cost (per ton processed) | US$11.51 |

| Processing Cost (per ton processed) | US$2.96 |

| G&A Cost | US$0.12 |

|

Operating Cash Costs (per ton processed)* |

US$1.75/lb |

|

Average Cash Cost (C1) ** |

US$1.84/lb |

|

Average All-In Sustaining Cost (C3)*** |

US$2.34/lb |

|

Initial Construction CAPEX |

US$515M |

|

Sustaining CAPEX Over LOM (Including OP and UG, SXEW and Leach Pad Expansion) |

US$1,221 M |

|

LOM Free Cash Flow (FCF) (Post Tax Undiscounted) |

US$2,407M |

|

Post-Tax NPV8% |

US$515M |

|

Post-Tax IRR |

15.3% |

Notes: Cactus PFS dated March 28, 2024 (1) Tonnage is denoted in short tons.

*Operating cash costs consist of mining costs, processing costs, and G&A. **Total cash coasts consist of operating cash costs plus transportation cost, royalties, treatment, and refinancing. ***AISC consist of total cash costs plus sustaining capital, closure cost, and salvage value.

The mine schedule for open pit mining at Cactus West consists of 75.6 Mton of leach ore grading 0.307% CuT over 8 years of mining, including one year of pre-production. The stockpile project has 76.5 Mton of leach ore grading 0.163 % CuT with a mine life of slightly more than 8 years. Initial ore from the Stockpile Project and Cactus West will be placed on the leach pad near the end of pre-production period, Year -1. The Cactus West pit and Stockpile Project will be mined concurrently each providing 12 Mt/y of leach material or 24 Mt/y of leach material combined. An additional 142.4 Mton of waste material is mined in Cactus West, while the stockpile project contains 5.5 Mton of waste.

The sublevel caving method was deemed to offer the best opportunity to maximise the conversion of resources to reserves whilst offering more favourable economic and production capacity outcomes compared to the other underground mining options considered for the Cactus East and Parks/Salyer deposits. Total Probable Reserves amount to 27.7 Mton @ 0.95 CuT% for Cactus East, and 96.2 Mton@ 0.93 CuT% for Parks/Salyer.

The initial Cactus East SLC level will commence 1,345 ft below surface and be comprised of 7 sublevels to a final depth 1,845 ft below surface. Access will be via a single decline with a portal located within the existing Cactus West pit. Ore haulage to surface will be via a vertical conveyor which can be supplemented with truck haulage to surface via the open pit if necessary. Production will continue for 11 years and will peak at 3.9 Mt/y.

The initial Parks/Salyer SLC level will commence 1,120 ft (341 m) below surface and include 11 sublevels to a final depth of 1,930 ft (588 m) below surface. Access to the Parks/Salyer deposit will be via a surface portal and twin declines. One will be dedicated to ore haulage using an inclined conveyor and the other providing access for personnel and equipment. Production will continue for 19 years and will peak at 6.9 Mt/y.

Material mined from the existing stockpile will be placed in 20-ft lifts and material from all other sources will be stacked in 30-ft lifts. Material will be reclaimed and transferred by haul truck to the crushing circuit where it will be crushed down to P80 minus ¾-in. From the crushing circuit, the material will transfer by overland conveyor to the agglomeration drums, mobile transfer conveyors, and mobile radial stacker to be placed on the lined heap leach pad facility. Leaching solutions, containing dilute sulfuric acid will be pumped and applied to the top of each lift and allowed to percolate though the copper leach material. Copper is dissolved into the solution while acid is consumed at approximately 6.5 lbs/ton of material leached. Acid consumption is net of regenerated acid in the SX/EW process and varies year over year from 220,000 tons of 94.5% sulphuric acid to net acid generating after year 7 when higher grades are mined from Cactus and Parks Salyer. The height of the leach material on the pad will eventually reach approximately 180 ft (55 m) in overall height.

The pregnant leach solution from the heap leach ponds will be pumped for processing in a copper SX/EW plant capable of producing initially up to 30,000 ton/y of copper cathodes with a design PLS flow of up to 12,000 gpm and grade at approximately 3.0 g/L Cu based on an overall 71% CuT recovery from the heap leaching methods for the resources considered. The solvent extraction plant is designed to be operated in a series, parallel, or series-parallel configurations with a single stage of stripping. The optionality of the solvent extraction plant will allow the plant to operate at 4,000 gpm, 8,000 gpm, or 12,000 gpm PLS flowrates based on the variability in copper grades and tonnages in the mine plan. The electrowinning circuit capacity will be expanded in Year 3, doubling in size to the overall plant capacity required to a nominal 60,000 ton/y of copper cathodes.

NPV and IRR Sensitivities(1)

|

Project Metric |

COPPER PRICE |

|||||

|

$3.75/lb |

BASE CASE $3.90/lb |

$4.00/lb |

$4.25 / lb Cu |

CURRENT Cu $ $4.50 / lb Cu |

||

|

Pre-Tax (8% disc) |

NPV |

$592 million |

$733 million |

$828 million |

$1,064 million |

$1,299 million |

|

Post Tax (8% disc) |

NPV |

$389 million |

$509 million |

$587 million |

$780 million |

$971 million |

|

|

IRR |

14% |

15.3% |

17% |

19% |

22% |

|

LOM Revenue |

$ millions |

$8,648 million |

$8,994 million |

$9,224 million |

$9,801 million |

$10,377 million |

|

LOM EBITDA |

$ millions |

$4,409 million |

$4,746 million |

$4,971 million |

$5,533 million |

$6,095 million |

|

Total Unlevered FCF (post-tax) |

$ millions |

$2,138 million |

$2,407 million |

$2,585 million |

$3,031 million |

$3,476 million |

|

NPV/Initial Capex Ratio (Post-Tax) |

|

0.8 |

1.0 |

1.1 |

1.5 |

1.9 |

Infrastructure

The Project exists in relatively flat to slightly undulating ranching and mining locale. The Project is surrounded by other, current and past-producing, copper mines and processing facilities. The Greater Phoenix area is a major population center (approximately 4.5 million persons) with a major airport and transportation hub and well-developed infrastructure and services that support the mining industry. The cities of Casa Grande and Maricopa are nearby and, combined with Phoenix, can supply sufficient skilled labor for the Project.

Onsite infrastructure from the prior ASARCO operation includes historic data and maps, core shack, vent raise, underground development towards Cactus East deposit, production shaft to 1,800 ft (549 m) level. Additionally, ASCU benefits from open pit access to near surface remnant mineralized material, permitted water wells and a water pond, access roads, rail access to the Union Pacific Railway, power substation and administration buildings. The TruStone building, a former onsite factory, has been refurbished and is now the site of ASCU's metallurgical testing, a core storage facility and a sample preparation lab. The former core shack has been modernized with power and A/C.

Electric power is available from Arizona Public Service’s (APS) 115 kV transmission line which passes on the south side of the site and connects to an existing substation at the mine site and is owned by APS.

Ecologically, the site is within the Sonoran Desert Section of the Basin and Range Lowlands Province of Arizona in the lower Santa Cruz Basin. The area is characterized by broad, level valley plains, gently sloping pediments, and widely separated mountain ranges. Elevations at the mine vary from approximately 1,360 ft amsl to 1,460 ft amsl. Soils have very low levels of available plant nutrients and vegetation typical of the Sonoran Desert and includes bunchgrasses, yucca, mesquite, and cacti.

Permitting and Social License

ASCU is dedicated to operating a responsible and carbon conscious mine site. It is the Company’s policy to ensure the community engagement and partnership outreach is developed and maintained with the support of the local communities.

As the Cactus Project is on private land, the permitting process is streamlined with no federal nexus, see below for required permits. The Company has confirmed with a Jurisdictional Delineation survey that no Federal Waters of the United States flow through the Cactus Properties. Permit approvals therefore, are limited to state and county regulatory bodies which have pre-determined approval processes and timelines. The Company aims to meet applicable requirements under the Clean Water Act (CWA), Clean Air Act (CAA) and all other applicable federal rules and regulations.

The Company has advanced the Cactus Project to the shovel-ready stage, receiving all major permits required as per the 2021 PEA. ASCU has received both the approval to draw water from the ADWR, and the Aquifer Protection Permit related to the Cactus PEA Mine Plan, the Dust Permit and Storm Water Pollution Prevention Plan, Mined Land Reclamation Plan and its Industrial Air Permit. Based on the Prefeasibility Study, certain amendments will be required as outlined below. The Company continues to make good progress with it’s permits and is supported by regulators and the community in its development plans.

The Cactus Project will require the following major permits and certifications:

1. Arizona Department of Water Resources (“ADWR”)’s Withdrawal of Ground Water for Mineral Extraction & Mineral Processing Permit: This permit is required for ground water withdrawal for mining operations. This permit was obtained in April 2021 and extends for 50 years, which is beyond the life of the project.

2. The ADEQ’s Aquifer Protection Permit (“APP”): This permit is required for owners or operators of facilities that could discharge a pollutant directly to an aquifer or to a land surface or vadose zone where there is a reasonable probability that the pollutant will reach an aquifer. The permit is valid for the life of the facility. This permit was obtained by ASCU for the Stockpile Project in July 2021 and becomes effective upon demonstration of financial capability submitted along with an amendment application in respect of the full project. Following development of the PEA mine plan in 2021, an amendment for full project coverage including expanded leach facilities, waste dumps and both open pit and underground infrastructure was obtained on March 28, 2022. Upon completion of the PFS in Q1/2024, the Company will require a second amendment based on the re-scoped operations.

3. Pinal County’s Air Quality Dust Control Permit: This permit is required for operations that have the potential to generate fugitive dust. This permit was obtained by the Company in January 2020 and is renewed yearly based on operational need.

4. ADEQ’s Arizona Pollutant Discharge Elimination System (“AZPDES”) Permits (construction and Multi‐Sector General Permit): This permit is for stormwater discharges that enter Arizona surface waters or a Municipal Separate Storm Sewer System. This permit was obtained for both the mine facility and the nearby TruStone facility which is situated on Company property.

5. Pinal County’s Industrial Air Quality Control Permit: This permit is required for operations that have the potential to generate particulate matter PM10 and/or PM2.5 that can affect air quality. This permit is renewed yearly and was received in May 2023, based on the Cactus PEA mine plan. Pending the PFS mine plan, an amendment will be required.

6. Arizona State Mine Inspector, Mined Lands Reclamation Permit: This permit relates to all metalliferous mining units and exploration operations with surface disturbances on private lands greater than five acres and has been received by the Company. Based on the pending PFS mine plan, an amendment may be required. The Company received this permit in March 2023.

In addition, the United State Army Corp. Of Engineers (“USACE”) Jurisdictional Determination 404 was received in February 2022. This is a determination as to whether Waters of the U.S. (“WOTUS”) are onsite or if the water on site contributes to a WOTUS waterway. ASCU received a determination that the Cactus project does not impact WOTUS, and therefore no Federal Permitting will be required.

Metallurgy

A comprehensive metallurgical testing program for the Cactus Project leachable material (oxides and enriched) has been underway since early 2020 consisting of sequential assaying, bottle roll testing and column leach testing for the mineral resources. The two year column testing program is ongoing at the Cactus Project collecting critical leaching information for both oxidized and secondary enriched ores with different rock types, ore grades, and mineralogy from both the Cactus and Parks/Salyer deposits. Results are demonstrating typical values reported in industry.

Average copper recovery and acid consumption estimates are presented in the table below, based on the May 2023 update.

TABLE 1: Updated Metallurgical Recoveries and Net Acid Consumption

|

Met Program (updated May 2023) |

Leach Cycle |

Recoveries |

Gross Acid Consumption (lb/ton) |

Net Acid Consumption (lb/ton) |

|

Stockpile (Oxide – 05/23) |

After 60 days |

90% |

22 |

16 |

|

Cactus (Oxide) |

90 day leach cycle |

92% |

22 |

16 |

|

Cactus (Enriched) |

200-220 day leach cycle |

73% |

21 |

0 |

|

Parks/Salyer (enriched – 05/23) |

Preliminary Results at 160 days |

80% |

22 |

0 |

A copper heap leach column testing program to delineate the metallurgical performance characteristics of the existing stockpile and remaining unmined copper resources at the Cactus mine has been ongoing since 2020. Results have been progressively reported in PEA, commensurate with Canadian National Instrument NI 43-101 reporting requirements. Since moving the 12 column metallurgical program to the TruStone Facility onsite, the program is QP'd by Jim Sorenson and managed by ASCU Projects Director, Dan Johnson and Cheif Metallurgist, Steve Dixon. The updated PEA has an effective date of August 31, 2022 and is authored by Stantec Consulting Services (“Stantec”).

Copper recovery is estimated for acid soluble copper (“CuAS”) and cyanide soluble copper (“CuCN”) content as determined by a standard sequential copper assaying methodology developed at the Skyline Laboratory facility in Tucson, Arizona. The CuCN assay fraction is classified as enriched secondary copper sulfide mineralization (e.g. chalcocite, covellite, digenite). The combined CuAS + CuCN content of the materials represents potentially soluble copper that is recoverable using heap leaching techniques (“CuSol”). Projected copper recovery estimates previously reported have been derived based on this leachable copper content and continues to be validated in the ongoing Prefeasibility Study (“PFS”) testing program.

Primary copper in mineralization that is not readily acid or cyanide copper soluble per the assay methods (e.g. native copper, chalcopyrite, bornite) reports in the total copper assay (“CuT”). Copper assayed that does not report in the soluble copper assay methodologies is not expected to provide meaningful recoverable copper contributions with the commercial methodologies anticipated.

The Company is assessing the leachability of its primary sulphide materials with third party companies. In June 2022, an exclusivity agreement with Rio Tinto was triggered by by successfully modelling the Cactus and Parks/Salyer samples and achieving the previously contemplated preliminary indicative metallurgical recoveries of at least 72% (copper recovery to cathode), under the Investor Rights Agreement. Nuton will continue to test the application of its copper heap-leach related technology to the primary sulphide component of the Cactus Mine and Parks/Salyer Projects through column leaching and scoping out capital and operating costs and design parameters.

Geology and Deposit Type

Ecologically the site is within the Sonoran Desert Section of the Basin and Range Lowlands Province of Arizona in the lower Santa Cruz Basin. Major host rocks are Precambrian Oracle Granite and Laramide monzonite porphyry and quartz monzonite porphyry. The porphyries intruded the older rocks to form mixed breccias; monolithic breccias and occur as large masses, poorly defined dike-like masses; and thin well-defined but discontinuous dikes. The deposit is structurally complex with intense fracturing, faulting, and both pre-mineral and post-mineral brecciation. It is bounded on the east and west sides by normal faults.

Chalcocite and covellite are the only supergene sulfides recognized. The chalcocite blanket in the mineralized zone is irregular in thickness, grade, and continuity. The thickness of leached capping varies from less than 100 ft (30 m) to over 650 ft (198 m), with the thicker intercepts on the north side. Substantial quantities of oxidized copper minerals are found erratically distributed through the capping. Chrysocolla, brochantite, and malachite are the most common oxidized copper minerals. In upper portions of the capping, chrysocolla predominates, while brochantite and malachite predominate in the lower portions.

The dominant hypogene alteration assemblages in the deposit are phyllic and potassic. The major hypogene sulfide minerals in the deposit are pyrite, chalcopyrite, and molybdenite. Hypogene sulfides occur as disseminated grains, veins, and vug fillings.

The Cactus deposit is a portion of a large porphyry copper system that has been dismembered and displaced by Tertiary extensional faulting. Porphyry copper deposits form in areas of shallow magmatism within subduction-related tectonic environments (Berger et al., 2008). Cactus has typical characteristics of a porphyry copper deposit which Berger et al. (2008) define as follows.

- One wherein copper-bearing sulfides are localized in a network of fracture-controlled stockwork veinlets and as disseminated grains in the adjacent altered rock matrix.

- Alteration and mineralization at 1 km to 4 km depth are genetically related to magma reservoirs emplaced into the shallow crust (6 km to over 8 km), predominantly intermediate to silicic in composition, in magmatic arcs above subduction zones.

- Intrusive rock complexes that are emplaced immediately before porphyry deposit formation and that host the deposits are predominantly in the form of upright-vertical cylindrical stocks and/or complexes of dikes.

- Zones of phyllic-argillic and marginal propylitic alteration overlap or surround a potassic alteration assemblage.

- Copper may also be introduced during overprinting phyllic-argillic alteration events.

History of the Sacaton Mine

The American Smelting and Refining Company (ASARCO) geologists first discovered the Sacaton mineral deposit in the early 1960’s while examining an outcrop of leached capping composed of granite cut by several thin monzonite porphyry dikes. The nature of this original find indicated the likely presence of porphyry copper-type mineralization. Following this lead, ASARCO initiated a drilling program which defined copper mineralization zones, targeting the sulfide ores, despite significant oxide zones at shallow depths. The west deposit contained an ore body which was ultimately accessed through the open pit. The deeper east deposit was the target of potential mining by underground methods, and today contributes significantly to the project economics.

The American Smelting and Refining Company (ASARCO) geologists first discovered the Sacaton mineral deposit in the early 1960’s while examining an outcrop of leached capping composed of granite cut by several thin monzonite porphyry dikes. The nature of this original find indicated the likely presence of porphyry copper-type mineralization. Following this lead, ASARCO initiated a drilling program which defined copper mineralization zones, targeting the sulfide ores, despite significant oxide zones at shallow depths. The west deposit contained an ore body which was ultimately accessed through the open pit. The deeper east deposit was the target of potential mining by underground methods, and today contributes significantly to the project economics.

ASARCO operated the mine from 1974-1984 with approximately 400 direct mine jobs created locally during the peak of operations, and numerous indirect positions also created to service the mine. During the course of operations, ASARCO processed 32 million tons of `, producing 400 million pounds of copper in addition to silver and gold from the West ore body through an onsite flotation mill. In 1982, construction began on two production shafts to 1,800 ft (549 m) depth and a headframe to the southwest of the pit to access the higher-grade East zone via underground mining methods; however, development was suspended due to market conditions and in 1984 and the mine shut down.

Whilst operating, the Sacaton mine site included crushing facilities, coarse ore stockpiles, a flotation mill, maintenance and administration buildings, core shack, a 390-acre tailings storage facility (TSF), a return water impoundment, an approximately 80-acre Alluvium Soil Storage Area, and a 500-acre stockpile of oxides and enriched material, at the time considered waste. All concentrates were shipped via rail to ASARCO’s smelter in Texas for processing into cathodes.

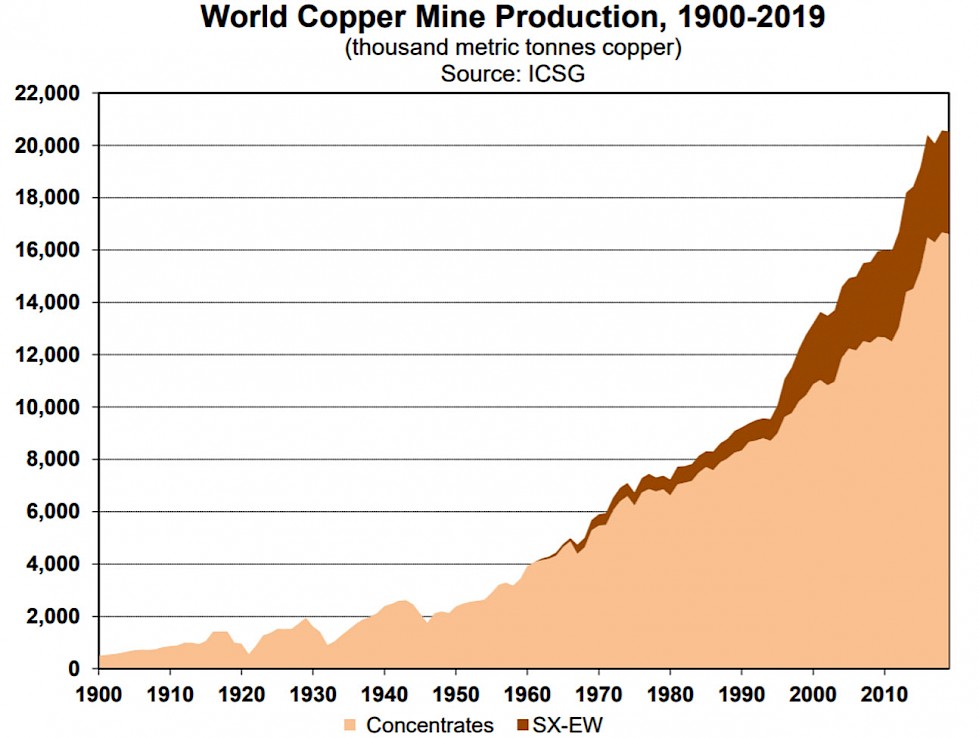

It is important to understand that while 16% of the worlds copper was produced in an SXEW plant in 2019 (see figure below), in the 1970’s, the process was still being refined and tested. ASARCO therefore planned the extraction of the Sacaton sulfide ore operations with a flotation mill, leaving behind a sizeable waste rock dump consisting of oxides and low-grade enriched ore and a significant in ground ore body. Today, ASCU can benefit from the refined SXEW process and will also be exploring the potential for primary ore leaching.

Following the 2020 ASARCO-funded mine site reclamation, the core shack, rail spur, power lines, waste rock and tailings facility remain in good condition. The vent raise and shaft are still in place; however, have had minimal assessment since the initial shut down of Cactus.

No un-remediated liabilities were transferred to ASCU during the purchase. The reclamation provided the company with a baseline environmental study approved by the Arizona Department of Environmental Quality (ADEQ).